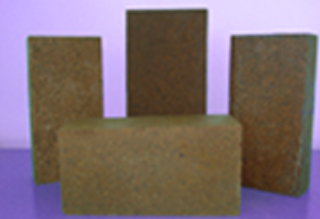

Light-weight thermal insulation refractory——Mg-Al-Mg Brick

Basic series refractory bricks. Alkaline refractory bricks refer to refractory products with basic oxides such as Mg0 and CaO as the main components. The main varieties of magnesium brick manufacturers are as follows.

(1) Magnesia-aluminum bricks refer to refractory bricks using magnesite as the raw material, periclase as the main crystalline phase, and MgO content of 80% to 85% or more. Its products are divided into two categories: metallurgical magnesia and magnesia products. According to the different chemical composition and uses, there are Martin sand, ordinary metallurgical magnesia, ordinary magnesia brick, magnesia-silica brick, magnesia-aluminum brick, magnesia-calcium brick, magnesia-carbon brick and other varieties. Magnesium refractory brick is the most important product among alkaline refractory bricks. It has a high degree of refractory, has good resistance to alkaline slag and iron slag, and is an important advanced refractory brick. Mainly used for open hearth furnace, oxygen converter, electric furnace and non-ferrous metal smelting.

(2) Dolomite brick is an alkaline refractory brick produced with dolomite as the main raw material. It is widely used in alkaline converters and can also be used as the lining of some refining packages outside the furnace.

(3) Forsterite refractory brick is a kind of refractory brick with forsterite 2MgO · SiO2 as the main composition. It is mainly used for grid bricks in open-hearth regenerative chambers, ingot bricks, bottoms of heating furnaces and in copper smelting furnaces.

Carbonaceous refractory brick. Carbon-containing refractory bricks refer to refractory brick products made of carbon or carbon compounds and containing carbon in different forms as the main component. They are mainly divided into the following types.

(1) Carbon brick is a high-temperature-resistant neutral refractory brick product made of carbonaceous material as the main raw material and added with an appropriate amount of binder. Carbon bricks are widely used in masonry blast furnace hearths, hearths, hearths and lower parts. Can improve the continuous operation time of the blast furnace and extend the service life. In addition, carbon bricks are also widely used in the electrochemical industry, chemical industry, petrochemical industry, electroplating industry, ferroalloy industrial furnaces (or equipment linings), acid and alkaline tank linings and pipes, and smelting non-ferrous metals (such as Lead, aluminum, tin, etc.).

(2) Graphite refractory products are refractory materials made of natural graphite as a raw material and clay as a binder. Such products include graphite clay crucibles, retorts, plug bricks for casting steel, nozzle bricks, and steel lining bricks. Among them, the most widely produced and widely used are graphite clay crucibles for steelmaking and melting nonferrous metals.

Address: Steel Industrial Park, Laobian District Industrial Park, Yingkou City, Liaoning Province Consulting Hotline: +86-133-5230-7686 +86-153-0417-8351

Technical Support: Yingkou Zhongchuang Network Technology Co., Ltd. All rights reserved.

Copyright ? Yingkou Sensheng Tenai Co., Ltd. All rights reserved record number:Liao ICP No. 19013533-1 Specializing in,Welcome to inquire! Technical Support:Xiangyun platform service support:Yingkou Zhongchuang Network Technology Co., Ltd.